At Thrasher Oilfield Services, we understand that precision calibration is the backbone of safe and efficient oilfield operations. That’s why we provide industry-leading calibration services tailored to the demanding requirements of hydraulic torque wrenches and other essential equipment.

Regular calibration ensures that your tools deliver accurate torque, maintaining the integrity of your operations and preventing costly equipment failures or safety hazards. By adhering to strict industry standards, calibration maximizes operational efficiency, reduces downtime, and extends the lifespan of your equipment.

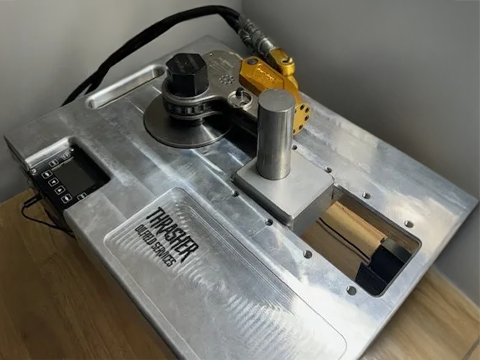

Our team of skilled technicians brings years of experience and advanced knowledge to every calibration project. We utilize state-of-the-art equipment to ensure precision measurements and adjustments, meeting and exceeding industry requirements. Whether you’re calibrating a single wrench or maintaining a fleet of tools, we provide reliable results every time.

1. Inspection

We begin with a comprehensive inspection of your equipment to identify any potential issues that could impact performance.

2. Precision Testing

Using cutting-edge diagnostic tools, we meticulously test torque delivery and ensure all components meet performance standards.

3. Adjustment & Tuning

If discrepancies are detected, our technicians perform precise adjustments to align your tools with required specifications.

4. Documentation

We provide detailed calibration reports for your records, ensuring compliance with safety and operational guidelines.

Our team of skilled technicians brings years of experience and advanced knowledge to every calibration project. We utilize state-of-the-art equipment to ensure precision measurements and adjustments, meeting and exceeding industry requirements. Whether you’re calibrating a single wrench or maintaining a fleet of tools, we provide reliable results every time.